Taking a strategic approach to metal and parts manufacturing can deliver a significant cost savings by eliminating inefficiencies that drain the bottom line. Full-service manufacturing optimizes the entire production process, especially when it comes to custom assembly, which reduces costly redundancies in packaging, handling, freight, and multiple markups. The need for assembly outsourcing is eliminated, resulting in reduced turnaround and subcontractor expenses.

But custom assembly is more than piecing together a few parts. For true ROI, assembly must be front and center early in the project design and engineering process. Machining and finishing also play key roles in delivering custom assembly value. Below is an ROI breakdown of the entire process, including the essential steps leading to cost-effective custom assembly.

Designing & Engineering for Custom Assembly ROI

Hindsight is 20/20 when you have to go back to the drawing board because a metal design failed to meet the required assembly criteria. A full-service manufacturer with in-house custom assembly capabilities typically employs engineers to work in tandem with designers to gain an early understanding of each product’s form, fit, and function.

Pre-assembly, designers and engineers can identify opportunities to reduce your product’s weight, manufacturing costs, and time to market. Such checks and balances at this stage may include:

- Optimizing product/tooling design and process parameters

- Testing the severity of tube expansion

- Predicting potential material thinning

- Determining failure/success rates for product performance

Potential flaws are then vetted before the pieces ever reach assembly, saving OEMs both time and money.

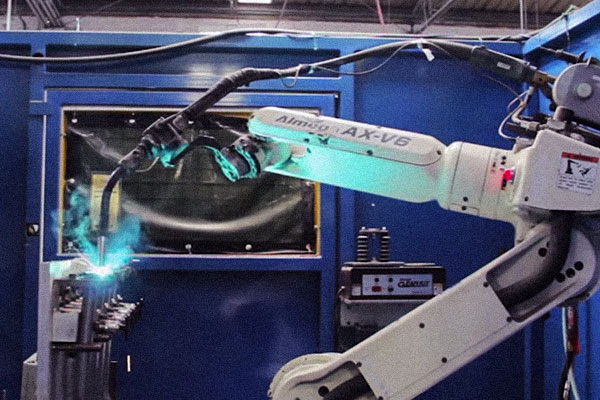

Metal Machining for Custom Assembly ROI

Metal machining works as the backbone to a successful custom assembly. Full service manufacturers can design and engineer custom machining services to meet your product’s exact design specifications per your assembly requirements. Custom machining also helps eliminate part inconsistencies and imperfections that cause expensive assembly rework and downtime.

Value-adding machining capabilities that lead to successful assembly may include:

- Metal drilling and tapping (flow drilling, for example)

- Metal punching

- Metal sawing and cutting

- Metal tube bending

- Automated deburring and sanding

Metal Finishing for Custom Assembly ROI

Metal finishing is the secret sauce to improving assembly turnaround time and reducing assembly expenses, but many vendors do not have this value-added capability in-house. A full-service manufacturer can match specific parts with the appropriate surface metal finishes to save time and production costs. There’s also the cost-savings of not having to outsource third-party vendors for finishing capabilities.

Additional finishing ROI benefits include:

- Pre-plated and post-plated materials

- Bright and brushed chrome, as well as stainless steel and brass

- Class A surface finishes

- Painted or stainless parts that can be finished from the same tool/machine

- Finishes that simulate hammered bronze and hammered nickel

- Vinyl clad and additional finishes

Cost-Saving Benefits of Custom Assembly

When sourcing the right manufacturing partner, versatility and breadth of capabilities can deliver true ROI, especially when the manufacturer can cost-effectively form, machine, finish, and custom assemble an entire project under one roof.

Bottom-line minded OEMs can benefit from custom assembly capabilities such as:

- Resolving design issues where parts have mounting requirements, but no methods to attach to the component (such as hole patterns and centers)

- Assisting with the mounting process, such as an oven window assembly by attaching outer frames and shipping the assembled product to the customer ready for drop in

- Adjusting packaging to reduce turnaround time, such as assembling finished handles per customer instructions, including extra tools and components, heat sealed to waterproof and shipped

At Mills Products, we specialize in cost-effectively piecing together every custom assembly for our OEM customers. Because we offer a diverse range of full-service manufacturing expertise, we can reduce our customers’ logistical headaches, solve quality control challenges, and reduce lead times for fast-tracking your project to market.

Contact us today to learn how we design, produce, machine, and custom assemble metal parts under one roof to cut costs and improve part consistency.