Superior powder coating and stainless steel finishing

Customers often ask us whether we can surface finish a particular part size, meet salt spray and corrosion resistance tests, provide heat-resistant paint or significantly reduce their finishing costs.

Yes to all of the above.

We provide high volume surface metal finishing and accurate color matching to meet the toughest finishing requirements.

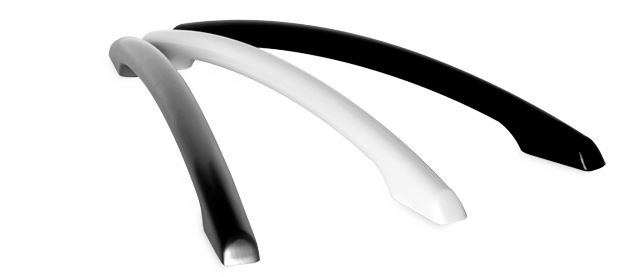

CUSTOM POWDER COATING

Our high-volume powder coating facility offers nearly 20 years of powder coating and forming experience under one roof, helping us achieve:

- Superior aesthetic appearance

- Multiple colors matched to design specification

- Corrosion and temperature resistance

- Eco-friendly powder coating operations with reclamation of unused powder

- Coating for appliances with strict alkaline testing requirements

SURFACE FINISHING

We help customers improve turnaround time and reduce costs by matching parts with various surface metal finishing capabilities.

We are one of the few surface finishing companies that offer stainless steel finishing. We also work with chrome, powder paint, faux stainless and polished finishes. Mills Products surface finishing capabilities include:

- Class A surface finishes

- Painted or stainless parts that can be finished from the same tool/machine

- Achieve finishes that simulate hammered bronze and hammered nickel

- Pre-plated and post-plated materials

- Bright and brushed chrome; stainless steel and brass

- Vinyl clad and additional finishes available