Full-service in-house machine shop for fully integrated prototyping

Our facility includes a CNC-equipped machine shop. Working closely with our clients’ design engineers, we can fabricate CNC milled parts from 3D models and 2D sketches. By lending our manufacturing expertise early on in the engineering process, we help anticipate any difficulties that may arise during production and often find ways to eliminate extra steps and costs.

We offer CNC milling machine services to all of our metal forming and assembly customers, as well as to companies who are looking for expertise just in this area. We can machine all types of material and can create single parts or production quantities.

3D MODELING CAPABILITIES

Our in-house 3D modeling capabilities allow us to revise customer models in order to accommodate machining. We also have the capability to create 3D solid models from customer 2D sketches and drawings, if necessary.

All of our CNC programming is done with GibbsCAM 3D machining software. We can accept 3D models in various formats, including .step, .iges, and Parasolid.

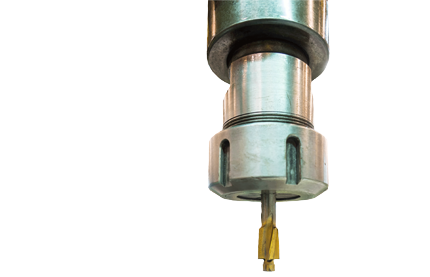

CNC MACHINING EQUIPMENT

Our CNC machining equipment includes:

- Two Fadal VNC 4020 Vertical Machining Centers

- 10,000 RPM spindle max

- Maximum part size 40” x 20” x 20”

- Maximum evenly distributed weight on table: 3,641 lbs.

- One Fadal VNC 6030 Vertical Machining Center

- 10,000 RPM spindle max

- Maximum part size 60” x 30” x 30”

- Maximum evenly distributed weight on table: 4,120 lbs.