Experts in hydroforming metal from aluminum to stainless steel

We were the first company to introduce tubular hydroforming to the appliance industry and are globally recognized for converting multi-part assemblies into lighter, stronger metal hydroformed parts.

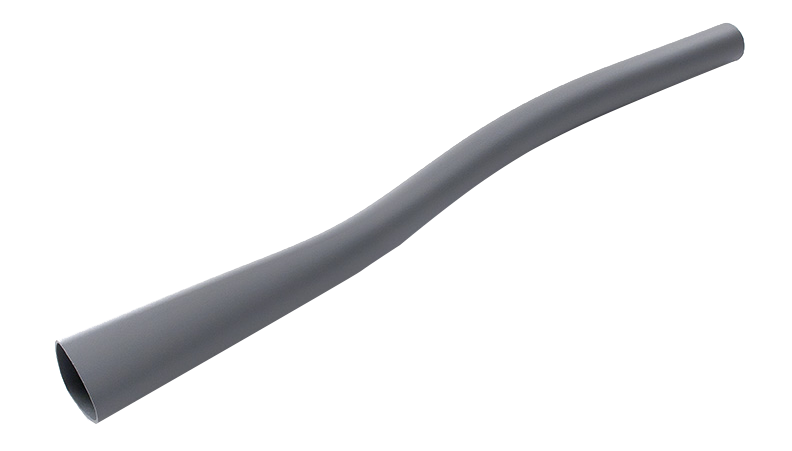

Our specialization in thin wall tubular hydroforming allows us to produce lightweight, complex parts with seamless aesthetics that would be impossible to cost-effectively reproduce using traditional forming methods.

TUBULAR HYDROFORMING BENEFITS

- Weight and part reduction opportunities

- Excellent bending strength and torsional stiffness

- Flexible design and engineering options

- High stiffness to weight ratio at low per unit costs

- Thin wall tubing capabilities

- Class A finishes

Hydroforming’s high strength-to-weight ratio produces high dimensional stability in fewer operations than traditional stamping or welding. Even better, we can introduce flexible design options such as large radius sweeps, cross-sectional shape transitions from round to elliptical, multi-sided cross sections and variable expansions of diameters of up to 35%.

COMMON TUBE HYDROFORMING APPLICATIONS

- Appliance handles

- Automotive exhaust components

- Bicycle frame components

- Automotive engine cradles

- Sink faucets

- Hand rails

- Chair or table legs

- Medical instruments

- Rifle scopes

- Sporting goods

OUR METAL TUBULAR HYDROFORMING PROCESS

We excel at condensing multiple parts into single, lightweight hydroformed parts.

- Largest tube hydroforming process machine is capable of 1,000 tons

- Largest bed size is 120″ X 60″

- Most of our machines have a maximum capacity of 30,000 PSI